CONVEYOR PROFILE CLEAN CASE STUDY

PROFILE CLEAN CASE STUDY

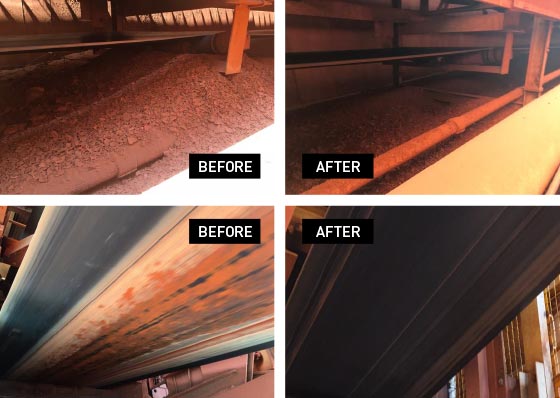

The CONVEYOR PROFILE CLEAN was experiencing high levels of carry back which was creating safety hazards impacting on the environment

The cleaner was 80+kgs in weight exposing the service technician to manual handling risks

The time to complete these maintenance activities was an extensive 3-4 hours

No maintenance adjustments could be made while the system was online

Clean up costs were in excess of $300,000 per year

Increase the efficiency of the conveyor belt cleaners to save clean up cost

Decrease the hazards associated with maintenance tasks for the service technicians

Decrease the maintenance activity time to reduce scheduled downtime

Ensure the unit was self adjusting that required no maintenance while online

THE IMPROVEMENT RESULTS:

Installation of Profile Clean Unit with standalone charge system requiring no adjustments

Increased saleable product cleaned from the belt into the chute for export

Unbelievable results in reducing material carry back along the system

Reducing the environmental impact from the carry back

Reduction in clean up costs under the conveyor system of $300,000

Extending the life of idlers, pulley lagging & the conveyor belt

The retractable unit can be removed with less than 30kg of pulling force

Reduction in maintenance in activity time by 80% (40 minutes to change tips)

No maintenance required for the life of the tip (20 weeks on this belt