WHY CHOOSE PROFILE CLEAN

WHY CHOOSE

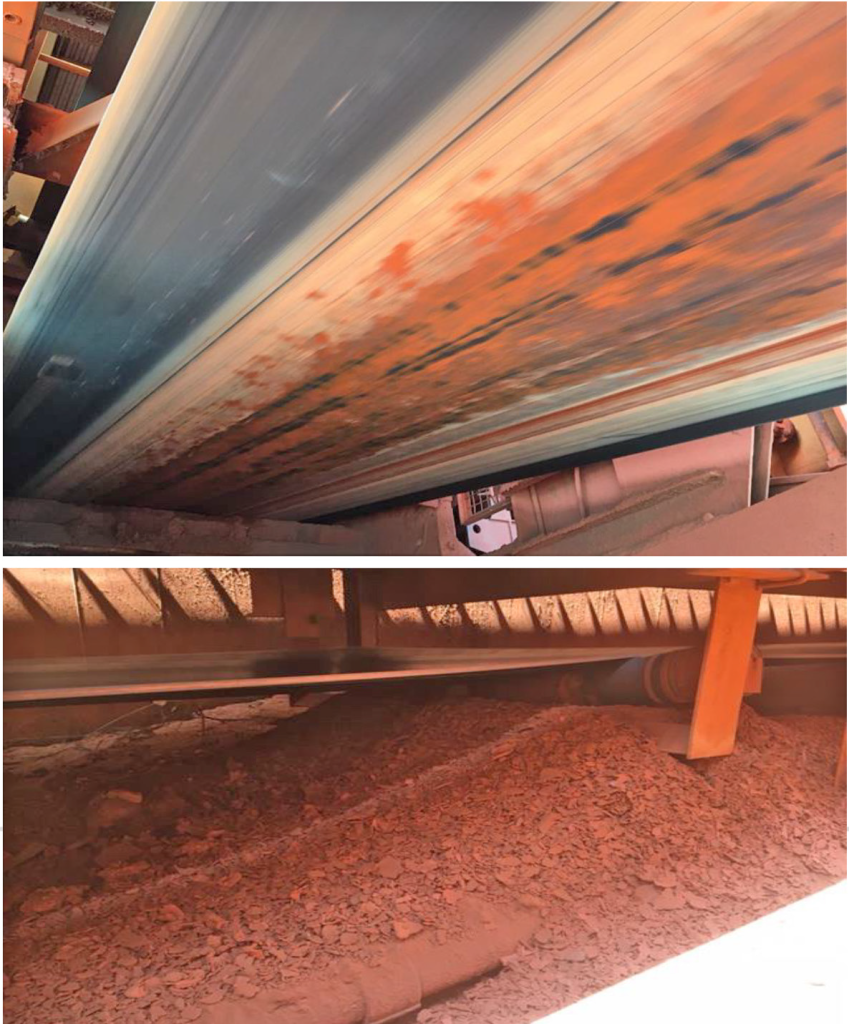

Conventional conveyor belt cleaners wear uneven causing tension on individual tips to decrease, resulting in reduced belt cleaner performance. CLEAN UP COST$

Conventional conveyor cleaners need to be continually maintained and adjusted by skilled labour. LABOUR COST$

Maintenance activity can involve high risk work. SAFETY RISK

Need to change all tips more regularly as they wear uneven and don’t apply constant pressure. ADDITIONAL PARTS COST$

Continual maintenance and adjustments required on the cleaner throughout the life of the tip by skilled labour. ADDITIONAL LABOUR COST$

Profile Clean does not require any adjusting for the life of the tip & no maintenance between shutdowns. LABOUR COST SAVING!

Profile Clean maintains the correct tension across the full tip face throughout the tip life pro longing the life of the tip. MATERIAL COST SAVING!

Profile Clean continually compensates for conveyor belt wear by automatically adjusting and applying constant tip pressure. CLEANER BELTS = CLEANER SITE!

Profile Clean is proven to extend the life of the idlers, pulley lagging the conveyor belt. REPLACEMENT PARTS COST SAVING!

Profile Clean requires minimal maintenance activities at longer intervals.

Before profile

cleaner install

- CONVENTIONAL BELT CLEANER

AFTER PROFILE

CLEANER INSTALL

- Profile Clean

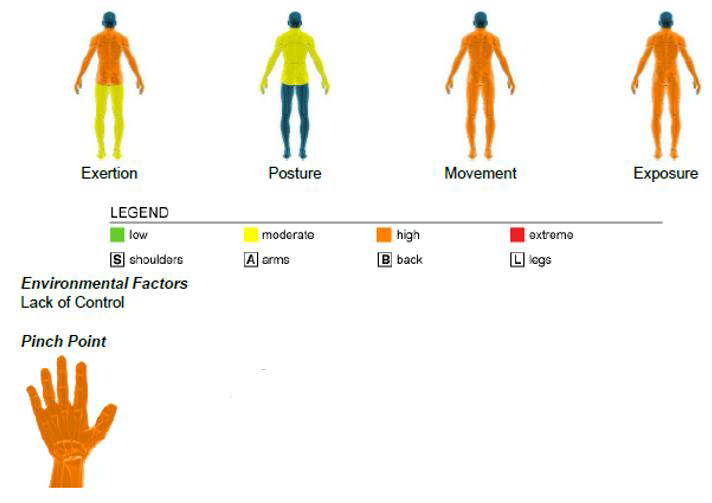

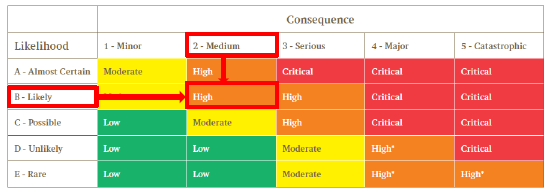

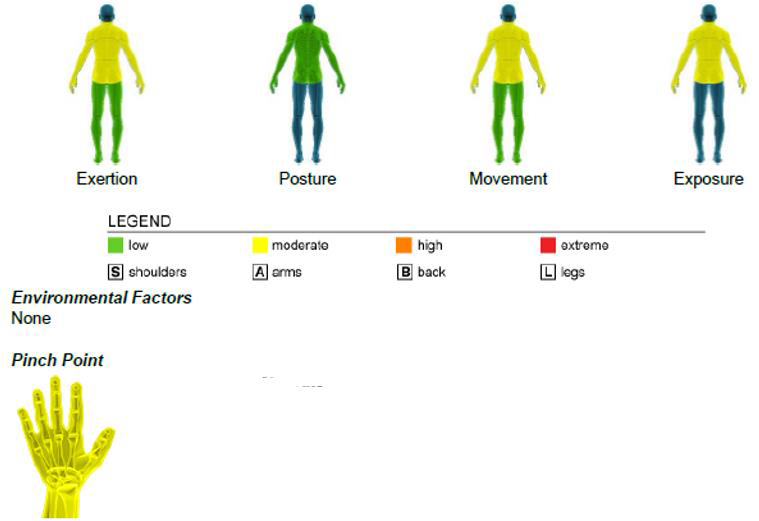

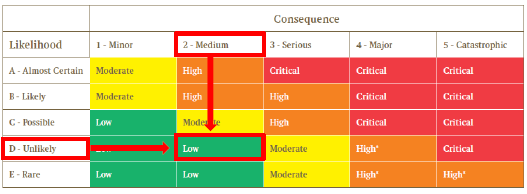

PROFILE CLEAN PROVEN MAINTENANCE ACTIVITY RISK REDUCTION

ERGO ANALYST REPORT FOUND:

50% risk reduction through Ergo Analyst study

Reducing the chances of Musculoskeletal injury to whole body as the task is not repetitive and does not require lifting over 15kg

Reduced pinch point potentials when changing scraper tips, with only one bolt for each tip

No requirement to access confined space or working at heights issues for maintenance

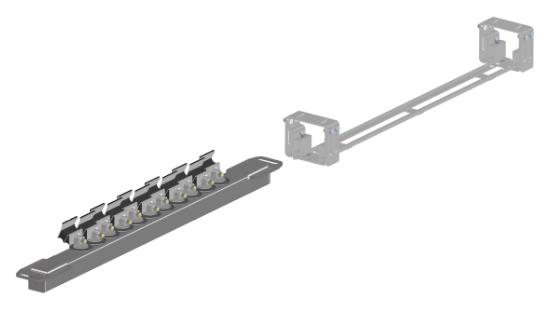

Pulling force of only 30kg to remove manifold

PROFILE CLEAN UNIQUE DESIGN FEATURES

PLC feedback options for remote monitoring capabilities with site functions (PSI read out or Pos/Neg)

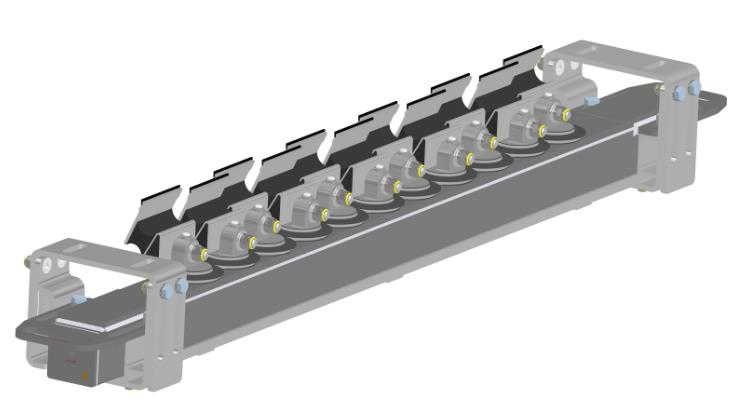

Compact design is easily interchangeable with existing P-style cleaners & easy to mount.

Fed by plant air or long life battery compressor the Profile clean automatically adjusts to the belt profile.

Profile Clean maintains the same attack angle on every tip throughout the entire tip life suited to the belt.

Options to make the manifold fully retractable for ease of maintenance or built in scenarios for installation on ship loaders/ stackers reclaimers & shuttles.

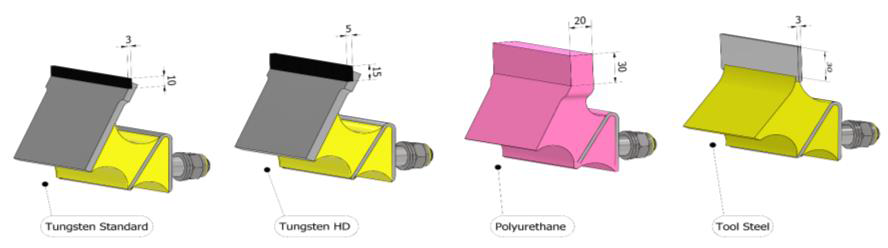

Interchangeable single bolt tip/cushion assembliesrequire no setting up after initial install.

Australian made and manufactured with full FEA’s, engineered drawings & cad files for site.